| Systems | Precondition | Industry | Vacuum | HTSC | LNG | Data |

| Cryosystems |

This method is superior to all other techniques as it is demonstrated by the comparison below.

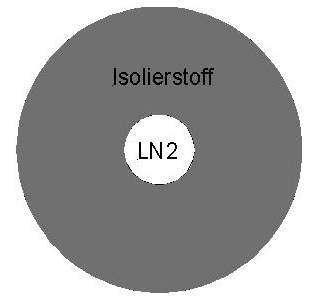

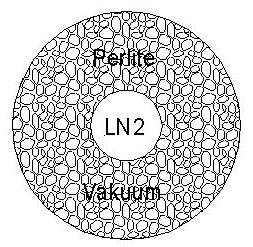

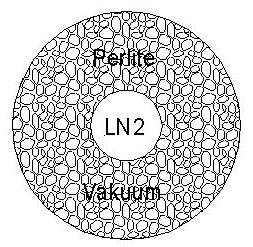

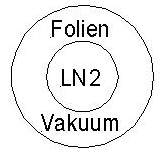

| F o a m i n s u l a t i o n 0,035 W/mK | V a c u u m p a n e l 0,004 W/mK | Perlite with vacuum 0,001 W/mK | High vacuum with refl. foils 0,00025 W/mK | |

| Heat loss (Watt)---> 1 m pipe length, 30 mm diameter | 20 | 16 | 4 | 1 |

| Insulation thickness (cm) | 10 | 1 | 1 | 1 |

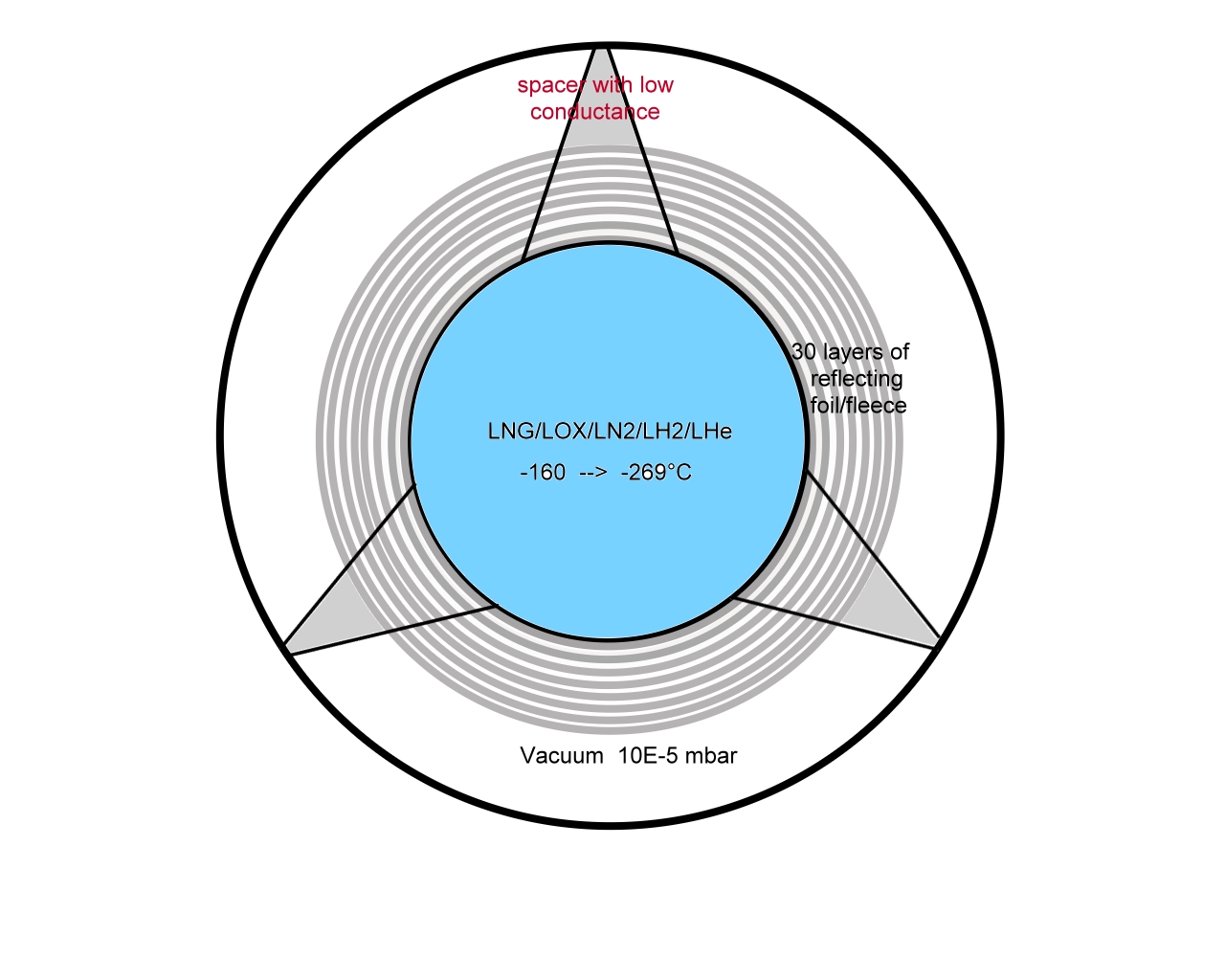

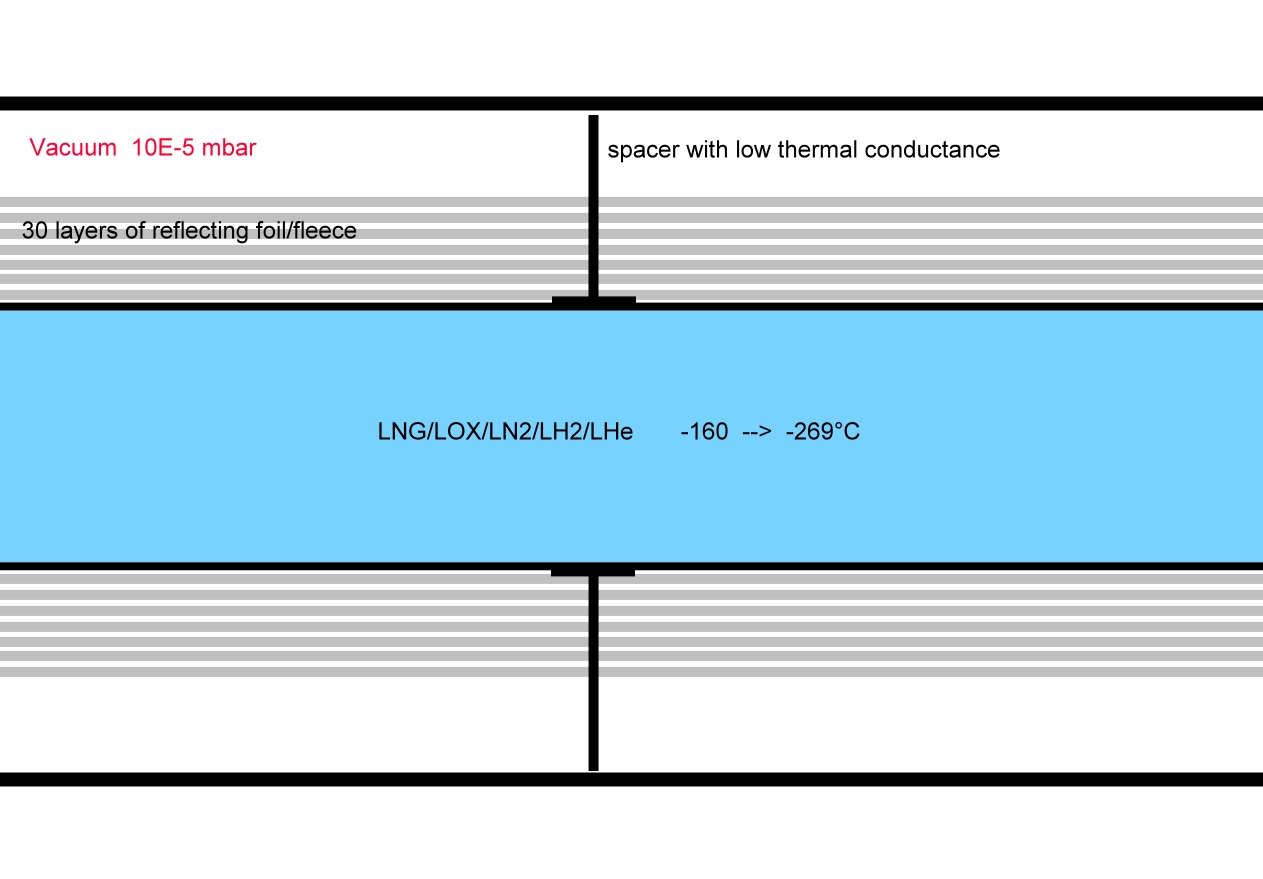

- vacuum <1x10E-5 mbar in cold condition

- vacuum stable for min. 2 years

- 30 layers super insulation

- vacuum checkable

- no cold spots on outer surface

Vacuum insulated transfer lines are the industry standard for the transfer of liquified gases.

If these systems are flexible in addition, they give excellend property for use.

Above you can see a typical transfer line.

A very low vacuum of less than 1x10E-5 mbar is important for a good insulation behaviour. At a vacuum of 1x10E-4 mbar the insulation is reduced by more than 50%. At 1x10E-3 mbar the insulation is reduced by several factors.

For long term vacuum it is not sufficient to pump it just down to a value of about 1x10E-5 mbar or lower. The use of getter, molecular sieve or charcoal helps to have a good vacuum behaviour for 10 years or longer.

| Pressure Range | Pressure (mbar) | Molecules per cm³ | Mean Free Path |

| Atmospheric pressure | 1013,25 | 2,7 x 10E19 | 68 nm |

| Low vacuum | 300 -> 1 | 10E19 -> 10E16 | 0,01 -> 100 µm |

| Medium vacuum | 1 -> 10E-3 | 10E16 -> 10E13 | 0,1 -> 100 mm |

| High vacuum (HV) | 10E-3 -> 10E-7 | 10E13 -> 10E9 | 100 mm -> 1 km |

| Ultra high vacuum (UHV) | 10E-7 -> 10E-12 | 10E9 -> 10E4 | 1 -> 10E5 km |

| Extremely high vacuum | <10E-12 | <10E4 | >10E5 km |

| Examples | |||

| Vacuum cleaner | 800 | 10E19 | 70 nm |

| Rotary pump | 1 -> 10E-3 | 10E16 -> 10E13 | 100 µm -> 10 cm |

| High vacuum insulated pipe | 10E-4 -> 10E-5 | 10E12 -> 10E11 | 1 m -> 10 m |

| Pressure on the moon | ~10E-11 | 4 x 10E5 | 10000 km |

| Interplanetary space | 10 | ||

| Interstellar space | 1 |

Pirani

Penning

please click......................................................................................please click

Spinning Rotor Gauge

please click......................................................................................please click

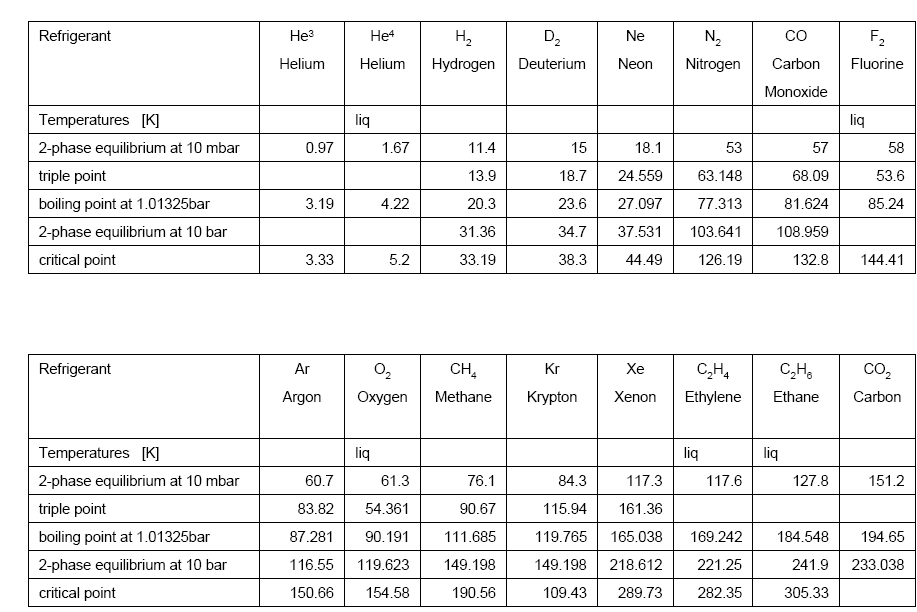

For some years HTS Cables can be manufactured to very long length with a working temperature at about -200°C.

If you cool down natural gas to about -163°C, it will become liquid. It is known as LNG (liquid natural gas). The volume is 1/600 of gas, the weight is 45% of water. Natural gas is 90% methan, rest is ethan, propan and others.

Natural gas is the fuel of the future, it is environmental friendly. Ferries will be driven by methan instead of diesel.

Using of LNG

At a temperature of -163°C tanks and tube systems should have a good insulation. Vacuum insulation plays an important roll. Flexible double tube systems can be used for insulation and for safety requirements.

| Material | Heat Conductivity W/(m*K) |

| Edelstahl | 15 |

| Glas | 0,76 |

| Glaswool | 0,035-0,05 |

| Polyurethan | 0,024-0,035 |

| Cork | 0,035-0,046 |

| Air | 0,0261 |

| Vacuum panel | 0,004-0,006 |

| Multilayer-Vacuum Insulation | 0,00025 |

1 Watt -> 173,5 g/h Evaporation of liquid helium

| Liquid for cooling | N2 | H2 | He |

| Metal (Stainless Steel) after cooling | 77 K | 20,4 | 4,2 K |

| Metal (Stainless Steel) before cooling | 300 K | 300 K | 300 K |

| Use of | kg liquid / kg metal | kg liquid / kg metal | kg liquid / kg metal |

| Evaporation | 0,43 | 0,2 | 4,2 |

| Evaporation + enthalpie of cold gas | 0,27 | 0,036 | 0,1 |